ELECON ENGINEERING COMPANY LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ELECON ENGINEERING COMPANY LTD.

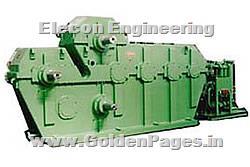

Assel Mill Gearbox

The Assel mill reduces and finishes the originally rolled mother tube. The finished seamless pipes are used for the races of antifriction bearings or even for other engineering applications. A tall, gigantic, rugged gearbox, having single input and three output with several idlers, drives this mill. The Assel mill gearbox is 5.1 metres long and 2.7 metres tall, weighing around 23 tons and capable of absorbing strong vibrations and shocks imparted by the tube rolling mill. The open aperture provided in the gearbox allows backward movement of hot working stock.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.